RFID tag is placed on items to identify or track those items over time or throughout their lifecycle. RFID tags can be used to track all types of objects in industries like healthcare, retail, and manufacturing, to keep track of assets or inventory. Each tag may vary significantly from another, which makes choosing one that has been designed to work in environments and applications similar to your application essential in order to achieve the best results.

RFID tags can cost as little as 10 cents or as much as $50 depending on the type of tag, the application and the volume of the order.

The cost of the tag should not be the determining factor when looking at RFID technology. While some tags may cost upward of $50, the return on the investment may be tenfold. For instance, some railroad companies are using $40 tags that are mounted on rail cars. These tags can be reprogramed thousands of times, meaning the cost of each time that tag is read and written to is less than one cent. The ROI in this case is tremendous.

UHF RFID hard tags are classified as such because they are rigid and thicker than the paper-thin labels/inlays. Hard tags are made from many types of materials such as polycarbonate, ceramic, ABS, steel, polystyrene, and polypropylene.

Because of the tougher exterior and larger size, these tags are more expensive than labels and inlays. Shapes and sizes of hard tags vary greatly, and can range from the size of a small pencil eraser to as large as a license plate.

Nearly all UHF RFID tags have special features that make them attractive to certain applications or environments, like Metal objects, Vehicle tracking, Medical management, etc.

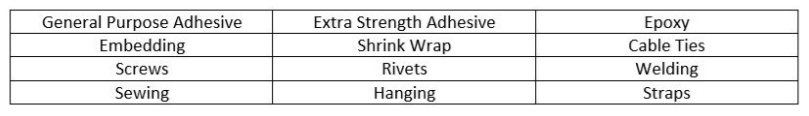

Inlays and labels use a permanent type of adhesive in most applications, while RFID hard tags vary depending on the tag type, weight, application, and application environment. Below is a list of commonly used attachment methods for RFID hard tags.

Deciding which attachment method to use will depend on the tag, item, and application.

1. Provide technical support

2. Artwork / number print;

3. Chip encoding;

4. RFID antenna and rfid tag shape design as per client’s requirement;

5. 100% testing before shipment

- RFID is a wireless technology mainly used to transfer data. The main purpose is to identify and track automatically a tag attached to an object.

- NFC as a subset of RFID, operates within the High Frequency (HF) range of the RFID spectrum. NFC is a short-range high-frequency wireless technology that enables devices and smartphones to establish communication with each other by touching them together or bringing them into proximity.

Both RFID or NFC technology are for cashless payment, transportation, identification, security, access control, etc.

Inlay can be understood as semi-finished products without encapsulation of RFID tags.

- RFID Dry inlay does not contain adhesive, and its structure is antenna + chip + chip package

- RFID Wet inlay contains adhesive, which can be directly attached to objects. The structure is antenna + chip + chip package + PET + Glue+ Release paper

- RFID Sticker contains adhesive and paper surface, which can print logo on the paper surface and attach to objects.